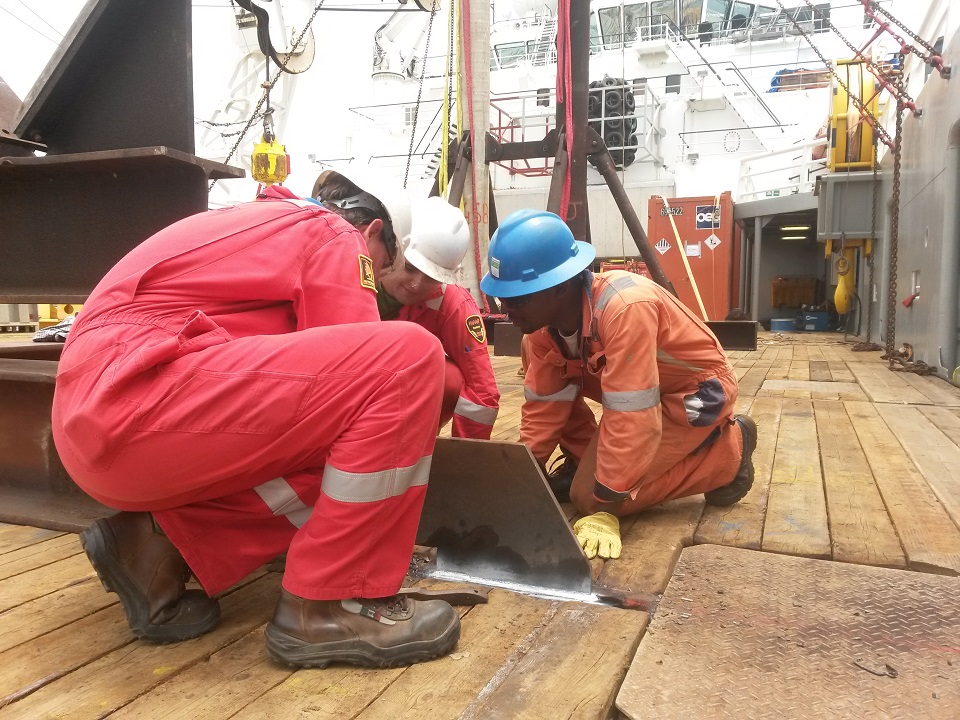

Seaweld Engineering was recently contracted by Tullow Oil Ghana Ltd. to seafasten Rigid Jumpers on the Rem Forza offshore support vessel for transportation to the Jubilee field.

Seafastening of the rigid jumper included fabrication of 18pcs of Type G1 gussets, 6pcs of type G2 gussets; and welding of 8pcs of type G1 gussets, 4pcs of type G2 gussets, 9pcs of 3T D-Rings and 49pcs of 15T D-Rings.

The project commenced on February 27th 2015 at the Takoradi Naval Base and took approximately five days to complete. It was successfully completed on time and budget, with our expert welders, fabricators, safety officers, MPI certified technicians and project engineers working day and night to ensure first class product quality and client satisfaction. Seaweld’s seafastening on the Rem Forza passed all quality test including Visual & Magnetic particle test inspections.

Seafastening is the act of securing cargo to marine vessels with the aim of preventing them from movement while the vessel is in transit and subjected to motions due to the nature of the seaway. Seafastening is typically designed to the specific transport vessel and cargo in question.

They are typically made out of steel plates or structural profiles which are welded to the ship deck.The Rem Forza is an IMO & MMSI registered multipurpose offshore transport vessel built in the year 2008. It currently serves as a transport vessel to the world class Jubilee oil field.

Seaweld is the recommended vessel seafastening expert offering high quality seafastening solutions for all offshore transportation with the capabilities of customizing solutions to suit your specific requirements.